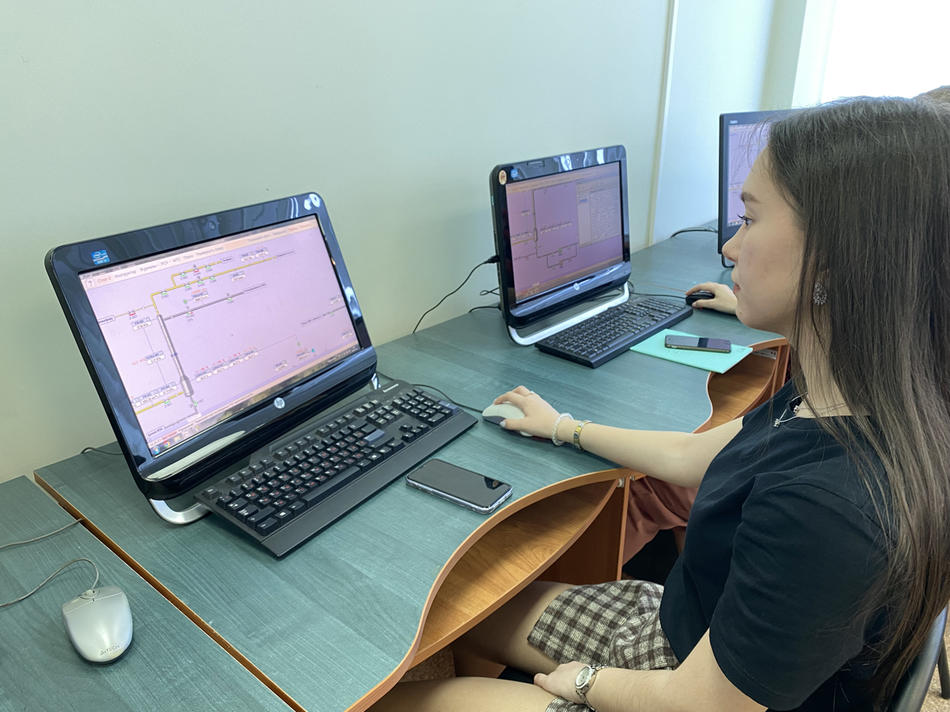

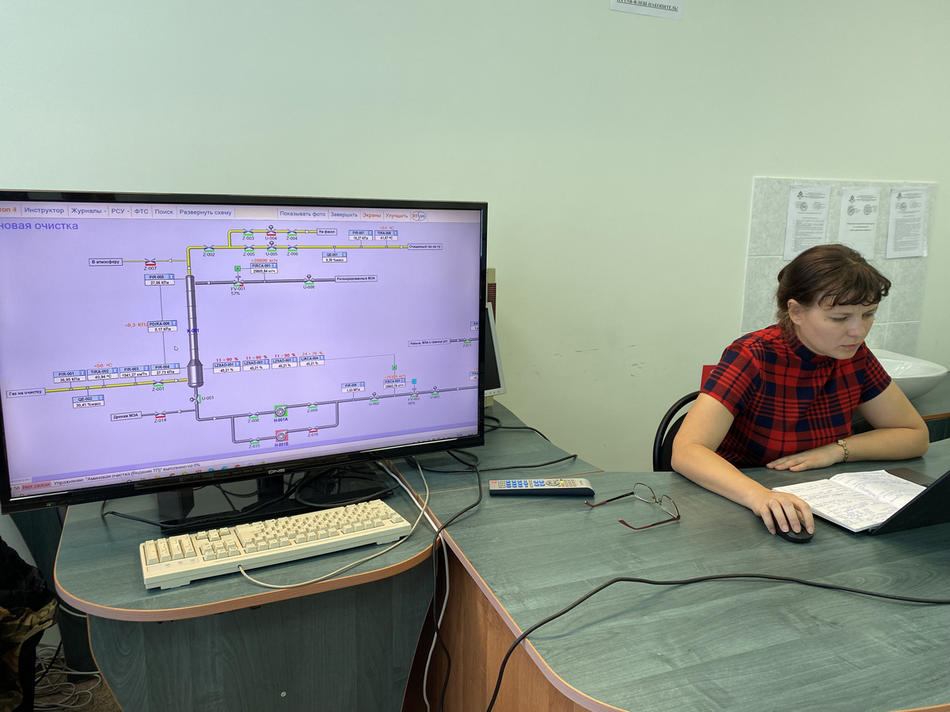

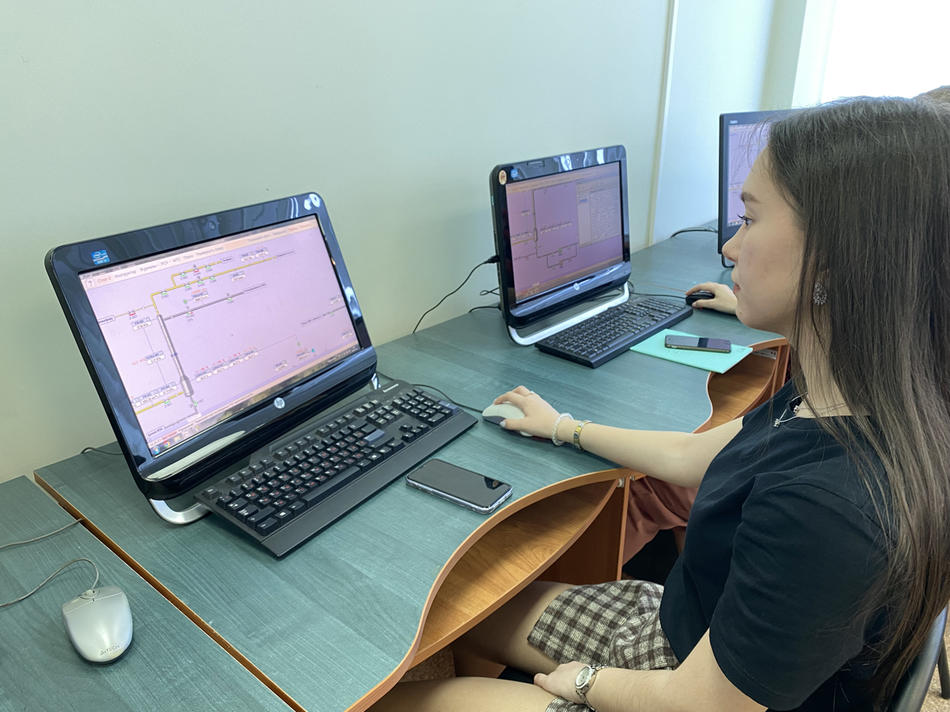

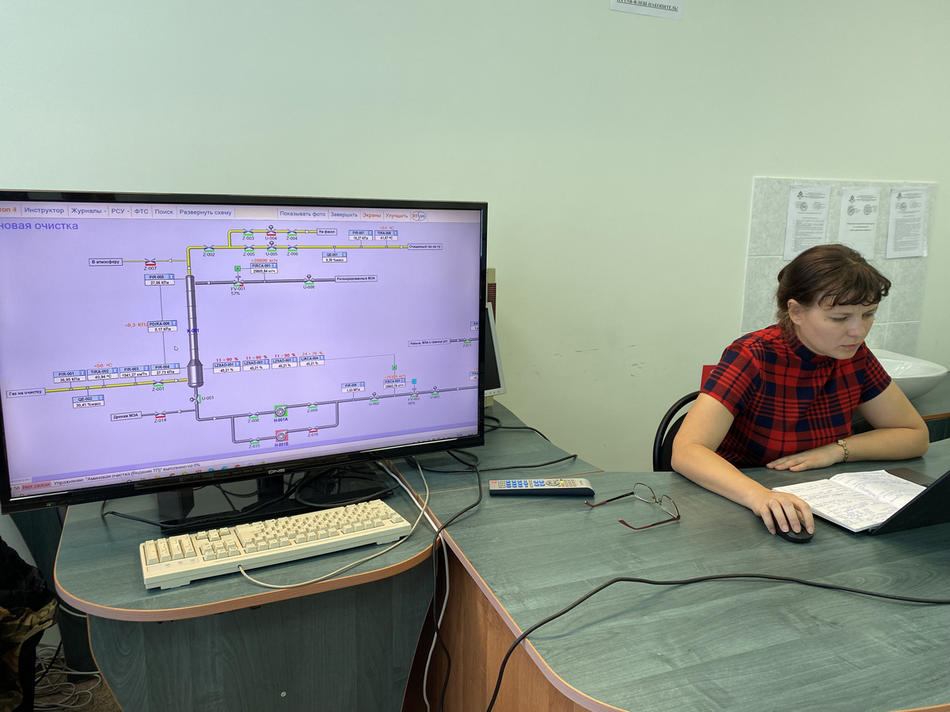

Students of ASTU (Astrakhan State Technical University) are trained on digital simulators

At the Institute of Oil and Gas of ASTU, students work out real production processes on a modern simulator.

Source: https://www.astu.org/Content/Article/27684

At the Institute of Oil and Gas of ASTU, students work out real production processes on a modern simulator.

Source: https://www.astu.org/Content/Article/27684

On August 31, the Tatarstan Oil and Gas Chemical Forum, one of the largest events in the domestic oil and gas industry, began its work at the Kazan Expo IEC

July 22, 2022 TPU will train future operators of technological plants with the help of Russian digital simulatorsBachelors and undergraduates of the Engineering School of Natural Resources of TPU will be trained…

May 20, 2022 Students of ASTU (Astrakhan State Technical University) are trained on digital simulatorsAt the Institute of Oil and Gas of ASTU, students work out real production processes on a modern simulator.

We cherish your opinion and take into account all the messages of our customers. After moderation of the appeal, the employee of the company will answer it. The response deadline is 7 calendar days.

We cherish your opinion and take into account all the messages of our customers. After moderation of the appeal, the employee of the company will answer it. The response deadline is 7 calendar days.

We cherish your opinion and take into account all the messages of our customers. After moderation of the appeal, the employee of the company will answer it. The response deadline is 7 calendar days.